Qualcomm Announces Snapdragon 8 Gen 5 Platform

Qualcomm added its latest smartphone platform to its premium-tier Snapdragon range.

Siemens announced a new Additive Manufacturing (AM) Process Simulation solution for predicting distortion during 3D printing. The product is fully integrated into Siemens’ end-to-end Additive Manufacturing solution, which assists manufacturers in designing and printing useful parts at scale.

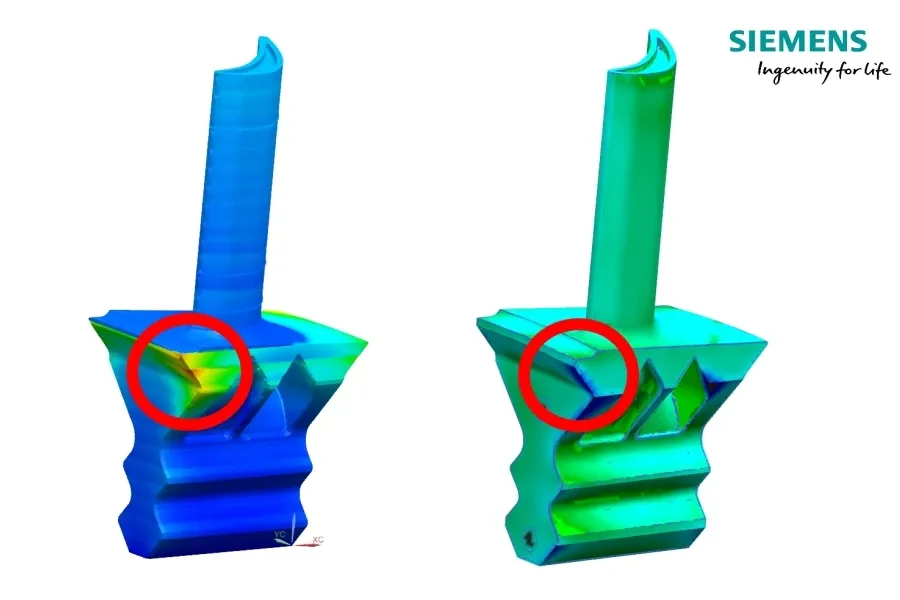

Building on Siemens’ comprehensive digital innovation platform and the Simcenter portfolio, the AM Process Simulation solution uses a digital twin to simulate the build process prior to printing, anticipating distortion within the printing process and automatically generating the corrected geometry to compensate for these distortions. This simulation is paramount for constructing a ‘first time right’ print, and necessary for achieving the efficiencies required of a fully industrialized additive manufacturing process.

"Using the Simcenter 3D AM Process Simulation solution at toolcraft will allow us to complete our additive manufacturing workflow," said Christoph Hauck, Managing Director, MBFZ toolcraft. "Through real-world testing, we have gained confidence that the Siemens AM Process Simulation solution will assist us in ensuring quality output from our print process.

When metal parts are 3D printed, the method used to fuse the layers of the print typically involves heat. As the layers build up, the residual heat can cause parts to warp inside the printer, causing various problems, from structural issues within the part itself to print stoppage. Issues such as these cause many prints to fail, and make getting a "first-time-right" print very difficult. Simulation of the printing process can help to alleviate many of these problems.

New process simulation product is integrated into the Powder Bed Fusion Process chain in the Siemens PLM Software Additive Manufacturing portfolio and is used to predict distortion for metal printing. The product provides a guided workflow to the user that allows for the assessment of distortions, the prediction of recoater collisions, prediction of areas of overheating, and other important feedback about the print process. The AM Process Simulation solution is expected to be available in January 2019, as part of the latest NX software and Simcenter 3D software.